| Sign In | Join Free | My tjskl.org.cn |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My tjskl.org.cn |

|

Model Number : SUP6

Place of Origin : China

MOQ : 1T

Price : $900-$1500/T

Payment Terms : Western Union, MoneyGram, L/C, T/T

Supply Ability : 5000T per Month

Delivery Time : within 20 days after the deposit

Packaging Details : in bundle

Material : SUP6

Standard : AISI, ASTM, DIN,BS

Dimension : 10-1000mm

Technique : Hot worked / forged cold draw

Application : Spring steel

Alloy or not : Alloy steel

Surface : polish or black

Legnth : 2-13m as customed

Tolerance : +-0.05mm or as your request

Place of orginal : China

Payment : T/T, L/C

Brand : Bao steel / TISCO

Delivery terms : CIF ,FOB ,CNF

Hot rolled alloy spring steel round bar SUP6 ASTM9620 55Si2Mn for small order

Alloy Steel Bar SUP6 Details

Chemical Composition and Machinical Properties SUP6

| Chemical Composition | Mechanical Properties(In Quenched & Tempered State) | ||

| C | 0.56-0.64 | Tensile strength(MPA) | ≥1274 |

| Si | 1.50-2.00 | Yield strength (MPA) | ≥1176 |

| Mn | 0.60-0.90 | Elongation(δ5/%) | ≥5 |

| Cr | ≤0.35 | Reduction in Area (ψ/%) | ≥25 |

| Ni | ≤0.35 | Impact (J) | --- |

| P | ≤0.035 |

Hardness |

Delivery hardness:321HB |

| S | ≤0.035 | ||

| Ni | ≤0.30 | ||

| Cu | ≤0.25 | ||

Equivalent Grades

| GB | ASTM | JIS | DIN | BS |

| 60 | A29M 1060 | S58C | C60 | 080A62 |

| 85 | A29M 1084 | SUP3 | Ck85 | 080A86 |

| 65Mn | A29M 1566 | |||

| 55Si2Mn | A29M 9260 | SUP6 | 55Si7 | 251H60 |

| 60Si2Mn | A304 , 9260H H92600(UNS) | SUP6 SUP7 | 60SiCr7 | 251H60 |

| 50CrVA | 6150 | SUP10 | 50CrV4 | 735A50 |

| 55CrMnA | A304 5155H H51550(UNS) | SUP9 | 55Cr3 | 525A58 527A60 |

Related Products

| JIS | Chemical Composition(%) | ||||||

|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Cr | V | |

| SUP3 | 0.75~0.90 | 0.15~0.35 | 0.30~0.60 | 0.035max | 0.035max | - | - |

| SUP6 | 0.56~0.64 | 1.50~1.80 | 0.70~1.00 | 0.035max | 0.035max | - | - |

| SUP7 | 0.56~0.64 | 1.80~2.20 | 0.70~1.00 | 0.035max | 0.035max | - | - |

| SUP9 | 0.52~0.60 | 0.15~0.35 | 0.65~0.95 | 0.035max | 0.035max | 0.65~0.95 | - |

| SUP10 | 0.47~0.55 | 0.15~0.35 | 0.65~0.95 | 0.035max | 0.035max | 0.80~1.10 | 0.15~0.25 |

| Type of steel | Hot-rolled hardness (HRC) | Annealed hardness (HRB) | Hardening | Tempering | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Temperature (℃) | Hardness(HRC) | Temperature (℃) | Temperature (℃) | Hardness(HRC) | ||||||

| JIS | SUP 3 | 44max | 95max | 830~860 oil quenched | 61min | 830~860 oil quenched | 450~500 air cooled | 36min | ||

| SUP 6 | 45max | 97max | 830~860 oil quenched | 54min | 830~860 oil quenched | 480~530 air cooled | 39min | |||

| SUP 7 | 46max | 97max | 830~860 oil quenched | 54min | 830~860 oil quenched | 490~540 air cooled | 39min | |||

| SUP 9 | 38max | 90max | 830~860 oil quenched | 55min | 830~860 oil quenched | 460~510 air cooled | 39min | |||

| SUP10 | 36max | 90max | 840~870 oil quenched | 55min | 840~870 oil quenched | 470~540 air cooled | 39min | |||

| Type of steel | Annealing Hardness | Deep-Drawing Hardness | |||

|---|---|---|---|---|---|

| Standard | Special | ||||

| HV | HV | HV | |||

| JIS | SUP3 | 190 | 170 | 180~280 | |

| SUP6 | 210 | 190 | - | ||

| SUP10 | 190 | 170 | 200~260 | ||

Application

used in making gear, crankshaft, trestle, hinge, oil tank, and cream pitcher etc

Packaging&Shipping

Company Main Products

| Structural Steel | 5140,5115,5120,5130,5145,4118,4130,4135,6150,5115,4142,4130,4118,6150,4140,4720,4320 |

| Mold Steel | H13,1.2344,SKD61,D2,SKD11,1.2379,1.2510,01,SKS3,95MnWCr5,D3,SKD1,1.2419, |

| Bearing Steel | GCr15,52100,SUJ1,SUJ2,100Cr6,1.2067,55C,8620,4320,9310,440C,M50,8620h |

| Spring Steel | 9260,SUP6,SUP7,1.7108,54SiCr6,1.7102,5155,SUP9,1.7176,5160,1.7177,6150, |

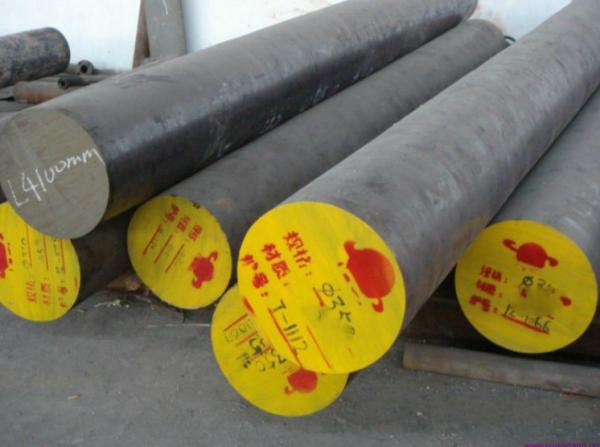

Picture Show

Surface Polished bar

Surface Bright Bar

Black & Grinding Surface Bar

Brand

FAQ

A: Currently we only do trading. Our founders are professionals in machining. We specialize in metallic parts manufacturing and work with one 3000 square meter well equipped machining center, one professional peeled steel rod/shaft manufacturer with long history and several small enterprises for welding and jointing.

A: Normally 30 days is required. We need a reasonable lead time to ensure quality.

A: (1)We make samples for your testing quality prior to batch production.

(2)We offer one year warranty for our products.A: We do OEM and protect our customer’s information, that means no exposure without our customer’s permission. You may refer to our transaction history for part of our exports.

Contact Information

Email: Ellieli8899@gmail.com

Skype:lifenjing_1988

Phone/Whatsapp:+86-151-22169604

|

|

hot rolled alloy spring steel round bar SUP6 ASTM9620 55Si2Mn for small order Images |